Program Overview

Gas-tight inspection machine is an essential inspection process in the production of lithium-ion batteries, which is used for testing the sealing of the top cover of power batteries after welding.

After the battery top cover is welded and evacuated, a certain pressure of helium gas is flushed into it, and a vacuum space with a certain degree of vacuum is outside the tested battery, which is connected to the leakage port of the helium detector. If there is a leak in the tested product, the helium gas leaking into the vacuum space can be measured by the helium detector, and the leak means the product is not sealed properly.

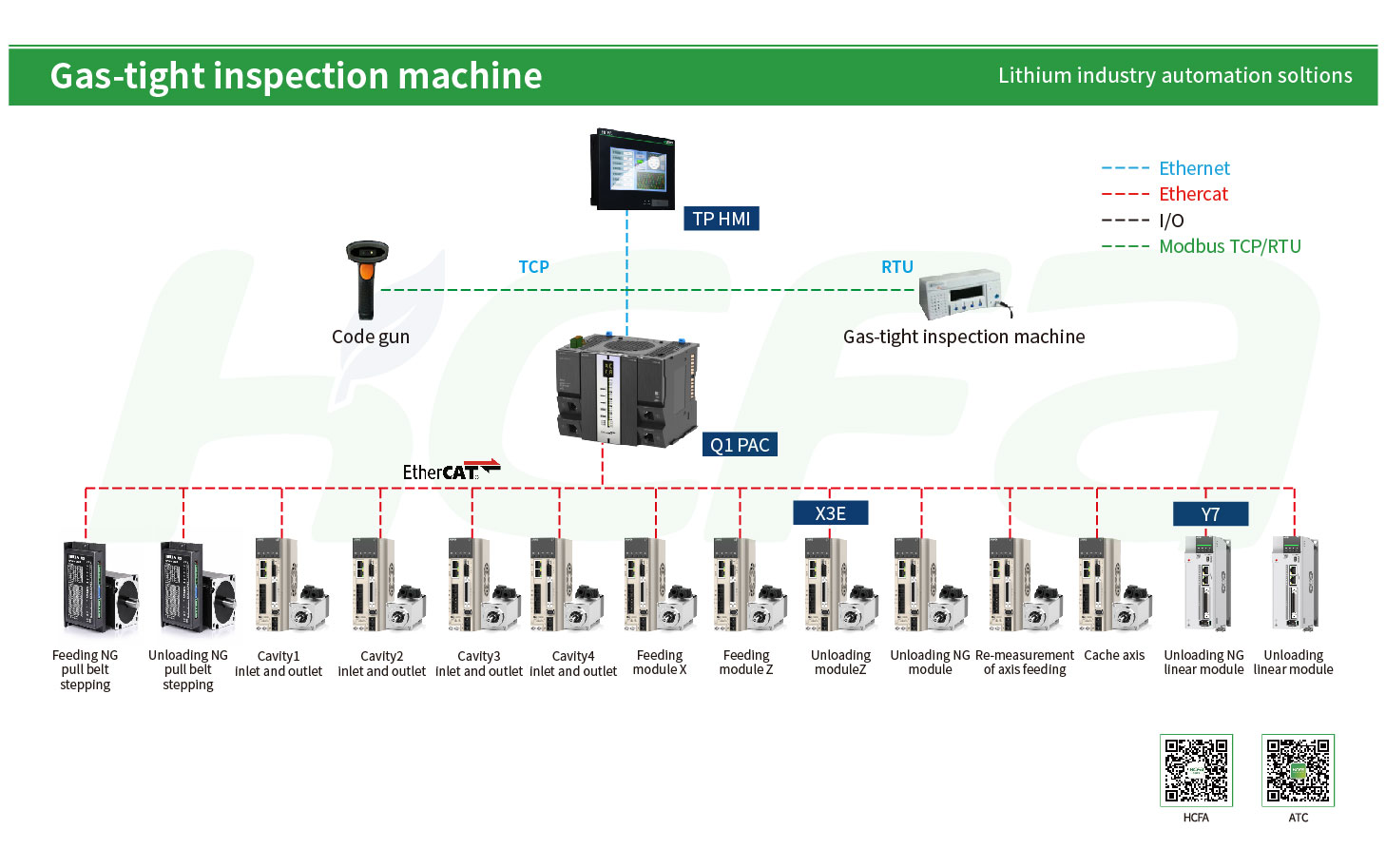

Our solution

Program Features

-

-

Short synchronization cycle

PAC multi-axis servo motion control, 16-axis synchronization cycle within 2ms

-

-

-

Rich communication protocols

Supports MODBUS TCP, MODBUS RTU, EtherCAT and other communication protocols

-

-

-

Ultra-high inertia motor

The inertia of the same power of the MG series servo motor is increased by more than 3 times, and the long belt shaft is smooth and stable with the bus drive control.

-

-

-

Linear Drive

New generation of high grade drive Y7 realize linear drive

-

-

-

High safety level

Protection class (IP67), highest safety protection (STO,STL)

-